Minutes from 8 of August 2007

Present: Richard Catheral,

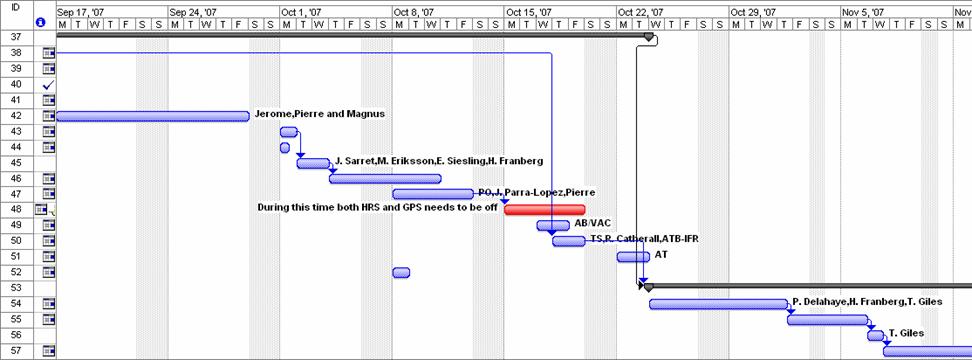

1) The existing beam-line needs to be taken out.

a.

b. Erwing, Jerome and Magnus will be available. Previous to this work, measurements and documentation of the positioning of the current beam line installation will be performed for eventual future re-installation.

c. A half day will be enough for the work.

2) Placing the RFQ into position, and alignments

a. The three support tables will be installed and markings on the floor need to be made. The trolleys will then be removed and the holes for fixation of the three platforms will be made before permanent installation of the three tables.

b. After a first mechanical alignment the fine adjustment for the alignment will be performed.

c. Pierre, Jerome, Magnus and Erwin will be available for this work.

d. One and a half week is planned for this.

3) Connection of the electronics.

a. J. Parra-Lopez and N. David

b. One week parallel with the alignments. No connections at the RFQ should be made before Jerome has finished the alignments.

4) Installation of the cage for the RFQ.

a. Richard will discuss with the company doing the platform installation. A possible entry from the GLM side will be kept and a door from the front-side.

b. Richard will ask Stephano to have a look at the drawings.

c. Eventually the gas bottle will be installed on the front side of the RFQ, but availability and possibility to change the bottle needs to be regarded.

5) Connection of the vacuum system and cooling water for the pumps.

a. Intervention in the HRS zone with both HRS and GPS off.

b. Leak detections for the vacuum needs to be installed.

c.

d. One week is planned for this work.

e.

f.

These vacuum pumps will not be integrated into the

ISOLDE control system this year.

6) Two days extra is given for conditioning the RFQ in a good vacuum and testing of the controls.

a. Someone from AB/VAC for eventual problems will be available.

b. Pierre and Tim from AB/OP for checks of the electronics connections.