![]()

Author

Ivan Podadera

Subject

Vacuum cavity

Prepared For

CERN

Project Created

Thursday, October 23, 2003 at 2:40:15 PM

Project Last Modified

Friday, October 24, 2003 at 9:01:58 AM

Report Created

Friday, October 24, 2003 at 9:09:35 AM

Software Used

Database

C:\RFQ mechanical drawings\Assembly cavity(for DS).dsdb

This report documents design and analysis information created and maintained using the ANSYS® engineering software program. Each scenario listed below represents one complete engineering simulation.

Scenario 1

The ANSYS CAE (Computer-Aided Engineering) software program was used in conjunction with 3D CAD (Computer-Aided Design) solid geometry to simulate the behavior of mechanical bodies under thermal/structural loading conditions. ANSYS automated FEA (Finite Element Analysis) technologies from ANSYS, Inc. to generate the results listed in this report.

Each scenario presented below represents one complete engineering simulation. The definition of a simulation includes known factors about a design such as material properties per body, contact behavior between bodies (in an assembly), and types and magnitudes of loading conditions. The results of a simulation provide insight into how the bodies may perform and how the design might be improved. Multiple scenarios allow comparison of results given different loading conditions, materials or geometric configurations.

Convergence and alert criteria may be defined for any of the results and can serve as guides for evaluating the quality of calculated results and the acceptability of values in the context of known design requirements.

The discussions below follow the organization of information in the ANSYS "Explorer" user interface. Each scenario corresponds to a unique branch in the Explorer "Outline". Names emphasized in "double quotes" match preferences set in the user interface.

All values are presented in the "Metric (mm, kg, MPa, °C, s)" unit system.

Notice

Do not accept or reject a design based solely on the data presented in this report. Evaluate designs by considering this information in conjunction with experimental test data and the practical experience of design engineers and analysts. A quality approach to engineering design usually mandates physical testing as the final means of validating structural integrity to a measured precision.

"Model" obtains geometry from the Autodesk® Mechanical Desktop® assembly "C:\RFQ mechanical drawings\Assembly cavity(for DS).dwg".

| Name | Material | Bounding Box (mm) | Mass (kg) | Volume (mm³) | Nodes | Elements |

|---|---|---|---|---|---|---|

| "OUT_CAVITY_1,OUTSIDE CAVITY_1" | "Stainless Steel" | 273.0, 327.5, 890.0 | 25.6 | 3.3×106 | 7928 | 3841 |

| "OUT_CAVITY_1,SUPPORT CAVITY_1" | "Stainless Steel" | 40.0, 70.0, 40.0 | 0.74 | 94,891.04 | 695 | 112 |

| "OUT_CAVITY_1,SUPPORT CAVITY_2" | "Stainless Steel" | 40.0, 70.0, 40.0 | 0.74 | 94,891.04 | 695 | 112 |

| "OUT_CAVITY_1,SUPPORT CAVITY_3" | "Stainless Steel" | 40.0, 70.0, 40.0 | 0.74 | 94,891.04 | 695 | 112 |

| "OUT_CAVITY_1,SUPPORT CAVITY_4" | "Stainless Steel" | 40.0, 70.0, 40.0 | 0.74 | 94,891.04 | 695 | 112 |

| "COVER_1,TOP_FLANGE_1" | "Stainless Steel" | 332.0, 15.0, 960.0 | 31.42 | 4.05×106 | 14151 | 7205 |

| "COVER_1,JOINT_SUPPORT_1" | "Stainless Steel" | 90.0, 12.0, 50.0 | 0.31 | 40,500.0 | 370 | 49 |

| "COVER_1,JOINT_SUPPORT_2" | "Stainless Steel" | 90.0, 12.0, 50.0 | 0.31 | 40,500.0 | 370 | 49 |

| "COVER_1,JOINT_SUPPORT_3" | "Stainless Steel" | 90.0, 12.0, 50.0 | 0.31 | 40,500.0 | 370 | 49 |

| "COVER_1,PIN_1" | "Stainless Steel" | 8.0, 20.0, 8.0 | 7.72×10-3 | 996.51 | 710 | 126 |

| "COVER_1,PIN_2" | "Stainless Steel" | 8.0, 20.0, 8.0 | 7.72×10-3 | 996.51 | 710 | 126 |

| "COVER_1,DAMY_FLANGES_1" | "Stainless Steel" | 109.0, 30.0, 109.0 | 0.16 | 20,169.02 | 2292 | 295 |

| "COVER_1,DAMY_FLANGES_2" | "Stainless Steel" | 109.0, 30.0, 109.0 | 0.16 | 20,169.02 | 2292 | 295 |

| "COVER_1,DAMY_FLANGES_3" | "Stainless Steel" | 109.0, 30.0, 109.0 | 0.16 | 20,169.02 | 2292 | 295 |

| "COVER_1,DAMY_FLANGES_4" | "Stainless Steel" | 109.0, 30.0, 109.0 | 0.16 | 20,169.02 | 2292 | 295 |

| "OUT_CAVITY_1,INJECTION_1,INJ_LI" | "Structural Steel" | 273.0, 301.5, 5.0 | 1.44 | 183,219.94 | 772 | 86 |

| "OUT_CAVITY_1,INJECTION_1,BEAM_P" | "Structural Steel" | 219.5, 219.5, 31.0 | 0.54 | 68,446.47 | 1668 | 195 |

| "OUT_CAVITY_1,INJECTION_1,FLANGE" | "Structural Steel" | 240.0, 240.0, 12.0 | 0.7 | 88,950.22 | 5509 | 2633 |

| "OUT_CAVITY_1,EXTRACTION_1,INJ_L" | "Structural Steel" | 273.0, 301.5, 5.0 | 1.44 | 183,219.94 | 772 | 86 |

| "OUT_CAVITY_1,EXTRACTION_1,BEAM_" | "Structural Steel" | 219.0, 219.0, 31.0 | 0.5 | 63,108.31 | 1668 | 195 |

| "OUT_CAVITY_1,EXTRACTION_1,FLANG" | "Structural Steel" | 240.0, 240.0, 12.0 | 0.7 | 88,950.22 | 5509 | 2633 |

| "OUT_CAVITY_1,FLANGE DN200 ISO-K" | "Structural Steel" | 240.0, 12.0, 240.0 | 0.7 | 88,950.22 | 5509 | 2633 |

| "OUT_CAVITY_1,SUPPORT_TOP_FLANGE" | "Structural Steel" | 332.0, 12.0, 960.0 | 6.59 | 839,995.09 | 16017 | 8312 |

| "OUT_CAVITY_1,CON_DAMY_ISO-K 63_" | "Structural Steel" | 31.0, 76.1, 76.1 | 0.16 | 20,673.82 | 896 | 112 |

| "OUT_CAVITY_1,CON_DAMY_ISO-K 63_" | "Structural Steel" | 31.0, 76.1, 76.1 | 0.16 | 20,673.82 | 896 | 112 |

| "OUT_CAVITY_1,FLANGE DN63 ISO-K_" | "Structural Steel" | 12.0, 97.0, 97.0 | 0.27 | 34,407.51 | 4151 | 2204 |

| "OUT_CAVITY_1,FLANGE DN63 ISO-K_" | "Structural Steel" | 12.0, 97.0, 97.0 | 0.27 | 34,407.51 | 4151 | 2204 |

| "OUT_CAVITY_1,BLANK_FLANGE DN63 " | "Structural Steel" | 12.0, 97.0, 97.0 | 0.65 | 83,285.58 | 2979 | 1541 |

| "OUT_CAVITY_1,BLANK_FLANGE DN63 " | "Structural Steel" | 12.0, 97.0, 97.0 | 0.65 | 83,285.58 | 2979 | 1541 |

| "COVER_1,FLANGE DN100 ISO-K_1,~~" | "Structural Steel" | 129.0, 12.0, 129.0 | 0.37 | 47,376.0 | 4402 | 2278 |

| "COVER_1,FLANGE DN100 ISO-K_2,~~" | "Structural Steel" | 129.0, 12.0, 129.0 | 0.37 | 47,376.0 | 4402 | 2278 |

| "COVER_1,FLANGE DN100 ISO-K_3,~~" | "Structural Steel" | 129.0, 12.0, 129.0 | 0.37 | 47,376.0 | 4402 | 2278 |

| "COVER_1,FLANGE DN100 ISO-K_4,~~" | "Structural Steel" | 129.0, 12.0, 129.0 | 0.37 | 47,376.0 | 4402 | 2278 |

| "COVER_1,BLANK FLANGE DN100 ISO-" | "Structural Steel" | 129.0, 12.0, 129.0 | 1.17 | 149,183.63 | 3704 | 1945 |

| "COVER_1,BLANK FLANGE DN100 ISO-" | "Structural Steel" | 129.0, 12.0, 129.0 | 1.17 | 149,183.63 | 3704 | 1945 |

| "COVER_1,BLANK FLANGE DN100 ISO-" | "Structural Steel" | 129.0, 12.0, 129.0 | 1.17 | 149,183.63 | 3704 | 1945 |

| "COVER_1,BLANK FLANGE DN100 ISO-" | "Structural Steel" | 129.0, 12.0, 129.0 | 1.17 | 149,183.63 | 3704 | 1945 |

| Name | Type | Associated Bodies | Normal Stiffness | Scope Mode | Behavior | Formulation | Initial Interface Treatment | Thermal Conductance |

|---|---|---|---|---|---|---|---|---|

| "Contact Region 5" | Bonded | "OUT_CAVITY_1,SUPPORT CAVITY_1" and "OUT_CAVITY_1,OUTSIDE CAVITY_1" | Program Controlled | Automatic | Symmetric | Pure Penalty | Adjusted to Touch | Program Controlled |

| "Contact Region 6" | Bonded | "OUT_CAVITY_1,SUPPORT CAVITY_2" and "OUT_CAVITY_1,OUTSIDE CAVITY_1" | Program Controlled | Automatic | Symmetric | Pure Penalty | Adjusted to Touch | Program Controlled |

| "Contact Region 7" | Bonded | "OUT_CAVITY_1,SUPPORT CAVITY_3" and "OUT_CAVITY_1,OUTSIDE CAVITY_1" | Program Controlled | Automatic | Symmetric | Pure Penalty | Adjusted to Touch | Program Controlled |

| "Contact Region 8" | Bonded | "OUT_CAVITY_1,SUPPORT CAVITY_4" and "OUT_CAVITY_1,OUTSIDE CAVITY_1" | Program Controlled | Automatic | Symmetric | Pure Penalty | Adjusted to Touch | Program Controlled |

| "Contact Region 22" | Bonded | "COVER_1,JOINT_SUPPORT_1" and "COVER_1,TOP_FLANGE_1" | Program Controlled | Automatic | Symmetric | Pure Penalty | Adjusted to Touch | Program Controlled |

| "Contact Region 23" | Bonded | "COVER_1,JOINT_SUPPORT_2" and "COVER_1,TOP_FLANGE_1" | Program Controlled | Automatic | Symmetric | Pure Penalty | Adjusted to Touch | Program Controlled |

| "Contact Region 24" | Bonded | "COVER_1,JOINT_SUPPORT_3" and "COVER_1,TOP_FLANGE_1" | Program Controlled | Automatic | Symmetric | Pure Penalty | Adjusted to Touch | Program Controlled |

| "Contact Region 25" | Bonded | "COVER_1,PIN_1" and "COVER_1,TOP_FLANGE_1" | Program Controlled | Automatic | Symmetric | Pure Penalty | Adjusted to Touch | Program Controlled |

| "Contact Region 26" | Bonded | "COVER_1,PIN_2" and "COVER_1,TOP_FLANGE_1" | Program Controlled | Automatic | Symmetric | Pure Penalty | Adjusted to Touch | Program Controlled |

| "Contact Region 27" | Bonded | "COVER_1,DAMY_FLANGES_1" and "COVER_1,TOP_FLANGE_1" | Program Controlled | Automatic | Symmetric | Pure Penalty | Adjusted to Touch | Program Controlled |

| "Contact Region 28" | Bonded | "COVER_1,DAMY_FLANGES_2" and "COVER_1,TOP_FLANGE_1" | Program Controlled | Automatic | Symmetric | Pure Penalty | Adjusted to Touch | Program Controlled |

| "Contact Region 29" | Bonded | "COVER_1,DAMY_FLANGES_3" and "COVER_1,TOP_FLANGE_1" | Program Controlled | Automatic | Symmetric | Pure Penalty | Adjusted to Touch | Program Controlled |

| "Contact Region 30" | Bonded | "COVER_1,DAMY_FLANGES_4" and "COVER_1,TOP_FLANGE_1" | Program Controlled | Automatic | Symmetric | Pure Penalty | Adjusted to Touch | Program Controlled |

| "Contact Region 14" | Bonded | "OUT_CAVITY_1,INJECTION_1,INJ_LI" and "OUT_CAVITY_1,OUTSIDE CAVITY_1" | Program Controlled | Automatic | Symmetric | Pure Penalty | Adjusted to Touch | Program Controlled |

| "Contact Region 15" | Bonded | "OUT_CAVITY_1,EXTRACTION_1,INJ_L" and "OUT_CAVITY_1,OUTSIDE CAVITY_1" | Program Controlled | Automatic | Symmetric | Pure Penalty | Adjusted to Touch | Program Controlled |

| "Contact Region 16" | Bonded | "OUT_CAVITY_1,FLANGE DN200 ISO-K" and "OUT_CAVITY_1,OUTSIDE CAVITY_1" | Program Controlled | Automatic | Symmetric | Pure Penalty | Adjusted to Touch | Program Controlled |

| "Contact Region 17" | Bonded | "OUT_CAVITY_1,SUPPORT_TOP_FLANGE" and "OUT_CAVITY_1,OUTSIDE CAVITY_1" | Program Controlled | Automatic | Symmetric | Pure Penalty | Adjusted to Touch | Program Controlled |

| "Contact Region 18" | Bonded | "OUT_CAVITY_1,CON_DAMY_ISO-K 63_" and "OUT_CAVITY_1,OUTSIDE CAVITY_1" | Program Controlled | Automatic | Symmetric | Pure Penalty | Adjusted to Touch | Program Controlled |

| "Contact Region 19" | Bonded | "OUT_CAVITY_1,CON_DAMY_ISO-K 63_" and "OUT_CAVITY_1,OUTSIDE CAVITY_1" | Program Controlled | Automatic | Symmetric | Pure Penalty | Adjusted to Touch | Program Controlled |

| "Contact Region 20" | Bonded | "OUT_CAVITY_1,SUPPORT_TOP_FLANGE" and "COVER_1,TOP_FLANGE_1" | Program Controlled | Automatic | Symmetric | Pure Penalty | Adjusted to Touch | Program Controlled |

| "Contact Region 21" | Bonded | "COVER_1,FLANGE DN100 ISO-K_1,~~" and "COVER_1,DAMY_FLANGES_1" | Program Controlled | Automatic | Symmetric | Pure Penalty | Adjusted to Touch | Program Controlled |

| "Contact Region 31" | Bonded | "COVER_1,FLANGE DN100 ISO-K_2,~~" and "COVER_1,DAMY_FLANGES_2" | Program Controlled | Automatic | Symmetric | Pure Penalty | Adjusted to Touch | Program Controlled |

| "Contact Region 32" | Bonded | "COVER_1,FLANGE DN100 ISO-K_3,~~" and "COVER_1,DAMY_FLANGES_3" | Program Controlled | Automatic | Symmetric | Pure Penalty | Adjusted to Touch | Program Controlled |

| "Contact Region 33" | Bonded | "COVER_1,FLANGE DN100 ISO-K_4,~~" and "COVER_1,DAMY_FLANGES_4" | Program Controlled | Automatic | Symmetric | Pure Penalty | Adjusted to Touch | Program Controlled |

| "Contact Region 34" | Bonded | "OUT_CAVITY_1,INJECTION_1,BEAM_P" and "OUT_CAVITY_1,INJECTION_1,INJ_LI" | Program Controlled | Automatic | Symmetric | Pure Penalty | Adjusted to Touch | Program Controlled |

| "Contact Region 35" | Bonded | "OUT_CAVITY_1,SUPPORT_TOP_FLANGE" and "OUT_CAVITY_1,INJECTION_1,INJ_LI" | Program Controlled | Automatic | Symmetric | Pure Penalty | Adjusted to Touch | Program Controlled |

| "Contact Region 36" | Bonded | "OUT_CAVITY_1,INJECTION_1,FLANGE" and "OUT_CAVITY_1,INJECTION_1,BEAM_P" | Program Controlled | Automatic | Symmetric | Pure Penalty | Adjusted to Touch | Program Controlled |

| "Contact Region 37" | Bonded | "OUT_CAVITY_1,EXTRACTION_1,BEAM_" and "OUT_CAVITY_1,EXTRACTION_1,INJ_L" | Program Controlled | Automatic | Symmetric | Pure Penalty | Adjusted to Touch | Program Controlled |

| "Contact Region 38" | Bonded | "OUT_CAVITY_1,SUPPORT_TOP_FLANGE" and "OUT_CAVITY_1,EXTRACTION_1,INJ_L" | Program Controlled | Automatic | Symmetric | Pure Penalty | Adjusted to Touch | Program Controlled |

| "Contact Region 39" | Bonded | "OUT_CAVITY_1,EXTRACTION_1,FLANG" and "OUT_CAVITY_1,EXTRACTION_1,BEAM_" | Program Controlled | Automatic | Symmetric | Pure Penalty | Adjusted to Touch | Program Controlled |

| "Contact Region 40" | Bonded | "OUT_CAVITY_1,FLANGE DN63 ISO-K_" and "OUT_CAVITY_1,CON_DAMY_ISO-K 63_" | Program Controlled | Automatic | Symmetric | Pure Penalty | Adjusted to Touch | Program Controlled |

| "Contact Region 41" | Bonded | "OUT_CAVITY_1,FLANGE DN63 ISO-K_" and "OUT_CAVITY_1,CON_DAMY_ISO-K 63_" | Program Controlled | Automatic | Symmetric | Pure Penalty | Adjusted to Touch | Program Controlled |

| "Contact Region 42" | Bonded | "OUT_CAVITY_1,BLANK_FLANGE DN63 " and "OUT_CAVITY_1,FLANGE DN63 ISO-K_" | Program Controlled | Automatic | Symmetric | Pure Penalty | Adjusted to Touch | Program Controlled |

| "Contact Region 43" | Bonded | "OUT_CAVITY_1,BLANK_FLANGE DN63 " and "OUT_CAVITY_1,FLANGE DN63 ISO-K_" | Program Controlled | Automatic | Symmetric | Pure Penalty | Adjusted to Touch | Program Controlled |

| "Contact Region 44" | Bonded | "COVER_1,BLANK FLANGE DN100 ISO-" and "COVER_1,FLANGE DN100 ISO-K_1,~~" | Program Controlled | Automatic | Symmetric | Pure Penalty | Adjusted to Touch | Program Controlled |

| "Contact Region 45" | Bonded | "COVER_1,BLANK FLANGE DN100 ISO-" and "COVER_1,FLANGE DN100 ISO-K_2,~~" | Program Controlled | Automatic | Symmetric | Pure Penalty | Adjusted to Touch | Program Controlled |

| "Contact Region 46" | Bonded | "COVER_1,BLANK FLANGE DN100 ISO-" and "COVER_1,FLANGE DN100 ISO-K_3,~~" | Program Controlled | Automatic | Symmetric | Pure Penalty | Adjusted to Touch | Program Controlled |

| "Contact Region 47" | Bonded | "COVER_1,BLANK FLANGE DN100 ISO-" and "COVER_1,FLANGE DN100 ISO-K_4,~~" | Program Controlled | Automatic | Symmetric | Pure Penalty | Adjusted to Touch | Program Controlled |

"Environment" contains all loading conditions defined for "Model" in this scenario.

Standard Earth Gravity

The following tables list local loads and supports applied to specific geometry.

"Solution" contains the calculated response for "Model" given loading conditions defined in "Environment".

It was selected that the program would choose the solver used in this solution.

| Name | Scope | Orientation | Minimum | Maximum | Alert Criteria |

|---|---|---|---|---|---|

| "Total Deformation" | All Bodies In "Model" | Global | 0.0 mm | 0.22 mm | None |

| "Equivalent Strain" | All Bodies In "Model" | Global | 8.05×10-9 mm/mm | 4.15×10-4 mm/mm | None |

| "Directional Deformation" | All Bodies In "Model" | X Axis | -0.21 mm | 0.19 mm | None |

| Name | Type | Value |

|---|---|---|

| Modulus of Elasticity | Temperature-Independent | 200,000.0 MPa |

| Poisson's Ratio | Temperature-Independent | 0.3 |

| Mass Density | Temperature-Independent | 7.85×10-6 kg/mm³ |

| Coefficient of Thermal Expansion | Temperature-Independent | 1.2×10-5 1/°C |

| Thermal Conductivity | Temperature-Independent | 0.06 W/mm·°C | Specific Heat | Temperature-Independent | 434.0 J/kg·°C |

| Name | Type | Value |

|---|---|---|

| Tensile Yield Strength | Temperature-Independent | 250.0 MPa |

| Tensile Ultimate Strength | Temperature-Independent | 460.0 MPa |

| Compressive Yield Strength | Temperature-Independent | 250.0 MPa |

| Compressive Ultimate Strength | Temperature-Independent | 0.0 MPa |

|

|

| Name | Type | Value |

|---|---|---|

| Modulus of Elasticity | Temperature-Independent | 193,000.0 MPa |

| Poisson's Ratio | Temperature-Independent | 0.31 |

| Mass Density | Temperature-Independent | 7.75×10-6 kg/mm³ |

| Coefficient of Thermal Expansion | Temperature-Independent | 1.36×10-5 1/°C |

| Thermal Conductivity | Temperature-Independent | 0.02 W/mm·°C | Specific Heat | Temperature-Independent | 480.0 J/kg·°C |

| Name | Type | Value |

|---|---|---|

| Tensile Yield Strength | Temperature-Independent | 207.0 MPa |

| Tensile Ultimate Strength | Temperature-Independent | 586.0 MPa |

| Compressive Yield Strength | Temperature-Independent | 207.0 MPa |

| Compressive Ultimate Strength | Temperature-Independent | 0.0 MPa |

|

The following table lists the files that you need to include for posting this report to an Internet or Intranet web server or for moving this report to a different location. Store all files in the same folder as the HTML page.

This report was originally generated in the folder "C:\RFQ mechanical drawings\ANSYS\Reports\".

| File Name | Description |

|---|---|

| "Vacuum chamber.htm" | This HTML page. |

| "StyleSheet.css" | The Cascading Style Sheet used to format the HTML page. |

| "CERNlogo.gif" | The Company image displayed at the top of the title page. |

| "AnsCompanyLogo.gif" | The ANSYS image displayed at the top of the title page. |

| "Table0001.jpg" | Table A2.1. "Thermal Conductivity vs. Temperature" Thermal Conductivity vs. Temperature |

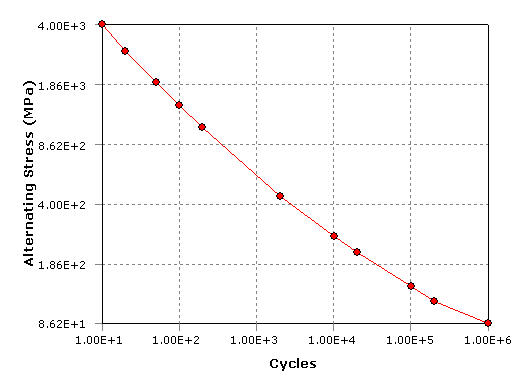

| "Table0002.jpg" | Table A2.2. "Alternating Stress vs. Cycles" Alternating Stress vs. Cycles |

| "Table0003.jpg" | Table A3.1. "Thermal Conductivity vs. Temperature" Thermal Conductivity vs. Temperature |